| Availability: | |

|---|---|

| Quantity: | |

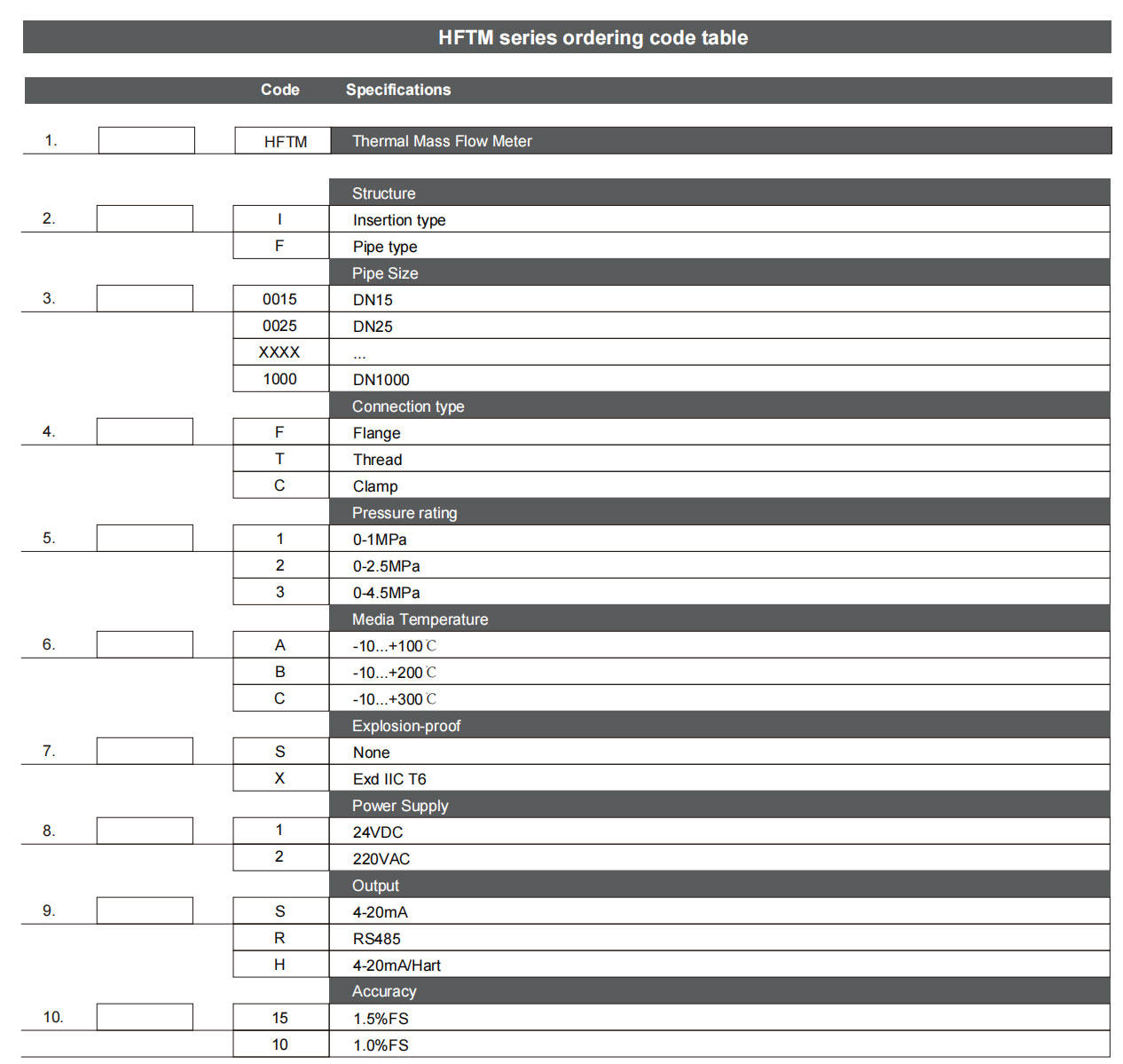

HFTM

ZYZL

ZYZL-HFTM

Measuring principle

Thermal mass flow measurement is all about heat transfer. When a gas or liquid flow passes a heated surface, it will take away the heat from the surface, absorbing this heat into the fluid. In a sense, such a flow has a cooling effect on the heated surface. The larger the flow, the more the heated surface will be cooled. By recording how much additional (electric) power is required to keep the cooled surface at the original temperature, you can calculate the amount of heat that is absorbed into the liquid flowing along the surface.

Application

ZYZL-HFTM series thermal mass flowmeter widely used in industrial processing plants – Pulp and Paper, Steel, Chemical, and Petrochemical Plants such as

- Semiconductor

- Solar PV

- Specialty Gas

- Power Industry

- Food & Beverage and Pharmaceutical.

- Oil & Gas/ Petrochemical

- Fine Chemical

For the insertion type, the measuring range according to the general speed mode classification as follows:

a.0.3 ~ 3.0 m/s | b.0.3~ 5.0 m/s | c.0.3 ~ 10.0 m/s | d.0.3 ~ 15.0 m/s |

e.0.4 ~ 20.0 m/s | f.0.6 ~ 30.0 m/s | g. 1.0 ~ 50.0 m/s | h. 1.2 ~ 60.0 m/s |

Note: The above list is for user to choose. Please choose the moderate flow rate to save calibration costs. Special attention should be paid to the speed limit of flammable gas. We recommend users to choose c, d, e, f velocity profile.

For inline flowmeter(i.e. with sampling tube), flow range based on the diameter of flow pipe, selection table at below.

pipe DN | Selectable flow range | |||

Prefer flow range | Maximum flow range | |||

Nm3/h | Kg/h( Air) | Nm3/h | Kg/h( Air) | |

15 | 1.9 ~ 19 | 2.3 ~ 23 | 0.4 ~ 40 | 0.5 ~ 48 |

20 | 3.4 ~ 34 | 4.1 ~ 41 | 0.7 ~ 70 | 0.8 ~ 84 |

25 | 5.3 ~ 53 | 6.4 ~ 64 | 1.1 ~ 110 | 1.3 ~ 132 |

32 | 8.7 ~ 87 | 10.5 ~ 105 | 1.7 ~ 170 | 2.0 ~ 205 |

40 | 13.6 ~ 136 | 16.4 ~ 164 | 2.7 ~ 270 | 3.3 ~ 325 |

50 | 21.2 ~ 212 | 25.5 ~ 255 | 4.2 ~ 420 | 5.1 ~ 506 |

65 | 35.8 ~ 358 | 43.1 ~ 431 | 7.2 ~ 720 | 8.7 ~ 867 |

80 | 54.3 ~ 543 | 65.4 ~ 654 | 11.0 ~ 1100 | 13.2 ~ 1325 |

100 | 85.0 ~ 850 | 102.3 ~ 1023 | 17.0 ~ 1700 | 20.5 ~ 2047 |

150 | 190.0 ~ 1900 | 228.8 ~ 2288 | 38.0 ~ 3800 | 45.8 ~ 4576 |

Note: 1. Flow range is reference to the gas of air and nitrogen . Other gas or not listed above please contact us for detail.

2. User need choose right pipe according to the relative flow range. Minimum and maximum are all measurable flow rate, the best measurable means the most accurate flow span. User can use commonly flow multiple 2 as full scale, please contact us if the full scale is overrun.

Accuracy | a . ±1.0 % F.S b . ±1.5 % F.S c . ±2.0 % F.S |

Explosion-proof grade | Ex d ⅡCT2 ~T6 Certificate of conformity :GYB16.1882X |

The measured gas | acetylene gas except. Measurement of oxygen users should pay attention to the oxygen flow rate and cleanliness! Explosive gases such as hydrogen, please aware of its Velocity of flow! |

Working pressure | 0 ~ 1.0MPa 0 ~ 2.5MPa 0 ~ 4.5MPa |

Gas temperature | -10 ~ +100℃ -10 ~ +200℃ -10 ~ +300℃ |

Working temperature | -10 ~ +55 ℃ |

Power supply | 24V DC±10 % ,≥350mA 220V AC(Apply to non explosive environment) |

Output signal | Standard:4 ~ 20mA DC; Selectable :RS485、HART |

Display(LCD) | Instantaneous 6 bit; b.Accountable 10 bit |

(With the intelligent flow totalizer in the remote control room, the instantaneous display is 5 bit and accountable 13 bit. Flow meter in the field needn’t display or only with instantaneous display in case of accountable differences.)