| Availability: | |

|---|---|

| Quantity: | |

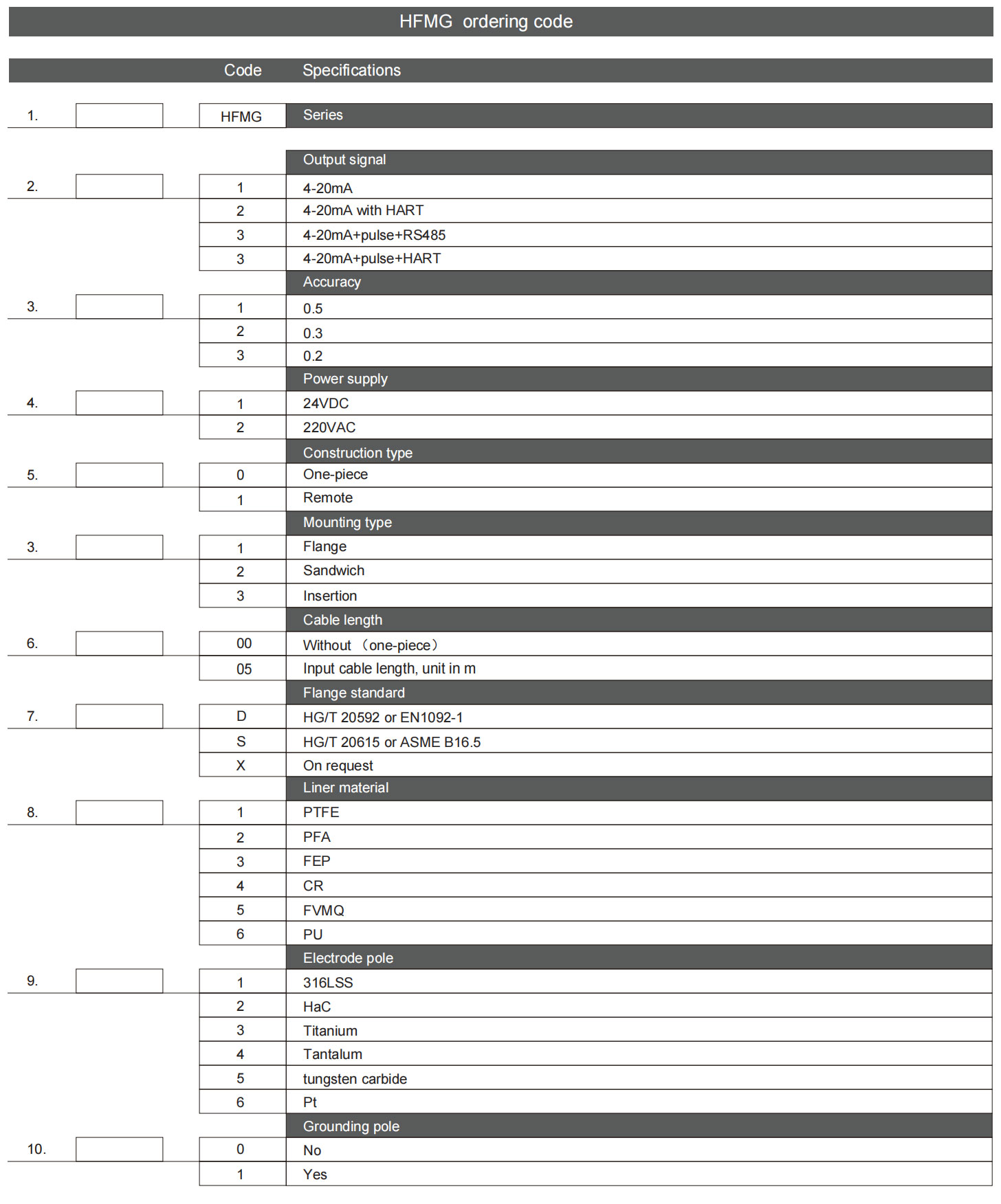

HFMG

ZYZL

ZYZL-HFMG

Product Description

The ZYZL Electromagnetic Flowmeter reduces lifecycle costs and unplanned shutdowns by accurately measuring water and wastewater flows in a variety of utility applications. The ZYZL Electromagnetic Flowmeter HFMG is supported by intelligent diagnostics that help users take advantage of improved installation, maintenance and process-management practices. With fully welded sensor construction and an isolated, replaceable terminal block the HFMG is the most dependable meter available for utility and water applications.

Electromagnetic Flowmeter HFMG is dedicated to chemical and process applications with corrosive liquids and highest medium temperatures. With its compact transmitter HFMG offers a high flexibility in terms of operation and system integration: access from one side, remote display and improved connectivity options.

● The bidirectional measuring principle is virtually independent of pressure, density, temperature and viscosity

● Dedicated to chemical and process applications with corrosive liquids and high medium temperatures

● Food and beverage

● Pharmaceutical machine

● Beverage filling machine

● Water treatment

Diverse applications – wide variety of wetted materials

Energy-saving flow measurement – no pressure loss due to cross-section constriction

Maintenance-free – no moving parts

Full access to process and diagnostic information

Measurement specifications | ||

Principle | Electromagnetic | |

Media range | Liquids (σ>1μS/cm) | |

Measurement value | Flow speed | |

Output value | Rate of flow | |

Accuracy | 0.5% ,0.3% or 0.2% | |

Repeatability | 0.16% ,0.1% or 0.06% | |

Wetted parts | ||

Material Body: Carbon steel with painting Electrode pole: 316LSS,HaC,Titanium,Tantalum,tungsten carbide, Pt Liner: PTFE,FEP,PFA,CR,FVMQ or PU | ||

Environment specifications | ||

Environment temperature | -20 … 85 °C | |

Media temperature | -40 ... 180℃ | |

Storage temperature | -40 … 70 °C | |

Ingress protection (EN 60529) IP67 or IP68 | ||

Enviroment humidity | < 98 % RH,without condensation | |

Output specifications | |

Output signal | 4-20mA,4-20mA with HART,RS485 or pulse |

Power supply | 24VDC or 220VAC |

Electrical connection | |

Connection type | Cable gland |

Electrical protection | |

Reverse polarity | Yes |

Short circuit | Yes |

Process connection | |

Flange standard | HG/T 20592 or HG/T 20615 |

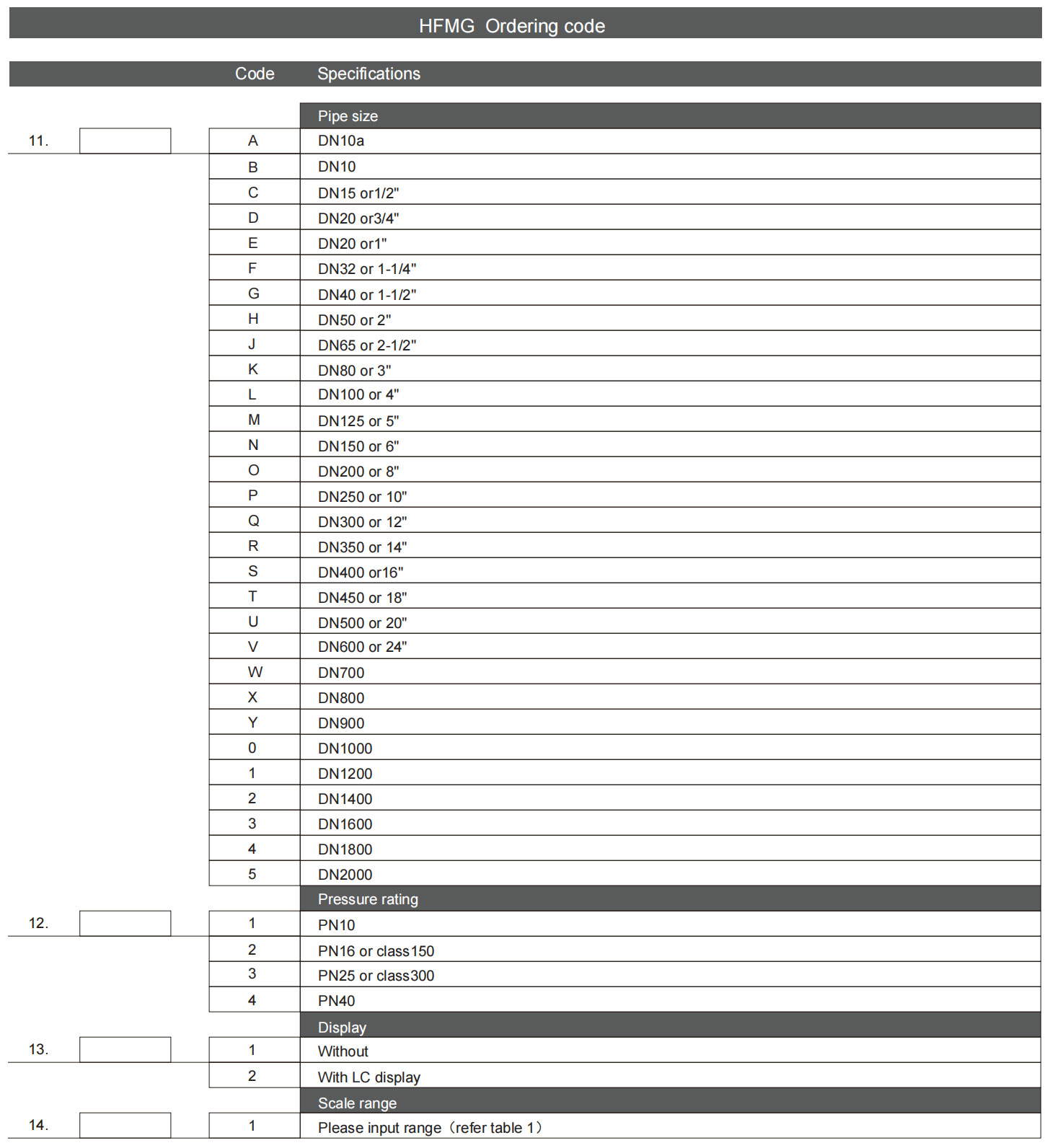

Pipe size | DN3 to DN2000 |

Mounting type | Flange or Sandwich |

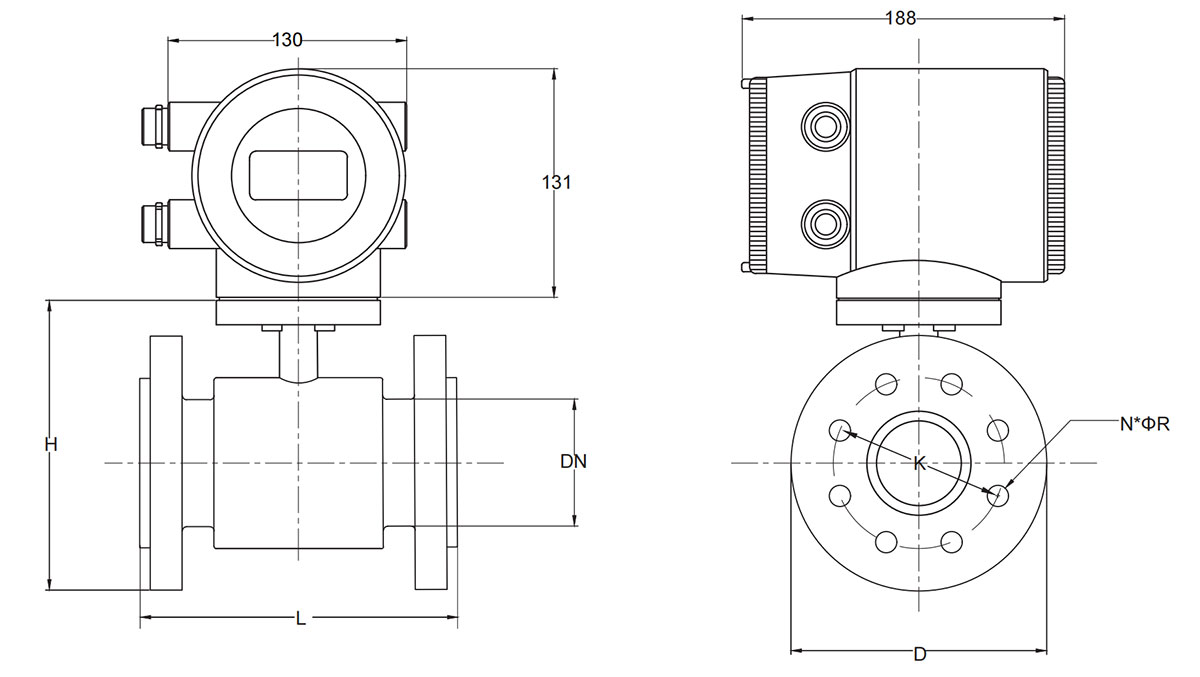

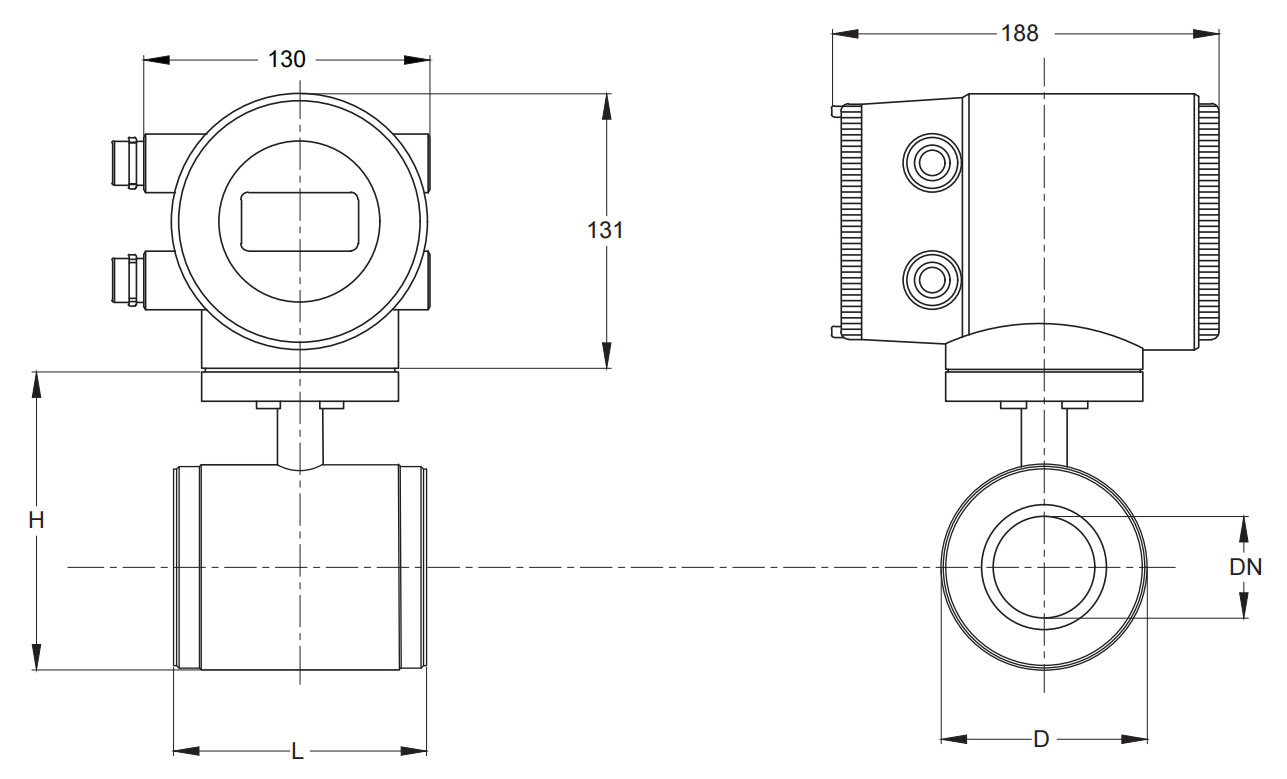

1) Flange type with LC display

Unit:mm

DN | 10a | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 |

PN(bar) | 40 | 16 | 10 | 10 | |||||||||||

L | 120 | 150 | 200 | 250 | 300 | 350 | 400 | ||||||||

D | 95 | 95 | 105 | 115 | 140 | 150 | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 395 | |

H | 142 | 142 | 147 | 152 | 172 | 177 | 205 | 216 | 228 | 258 | 284 | 315 | 366 | 420 | |

K | 60 | 65 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 350 | |

N*R | 4*14 | 4*18 | 8*18 | 8*22 | 8*22 | 12*22 | |||||||||

DN | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 |

PN(bar) | 10 | 6 | |||||||||||||

L | 450 | 500 | 600 | 700 | 800 | 900 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | |||

D | 445 | 505 | 565 | 615 | 670 | 780 | 895 | 1015 | 1115 | 1230 | 1405 | 1630 | 1830 | 2045 | 2265 |

H | 470 | 525 | 580 | 629 | 682 | 791 | 890 | 1007 | 1118 | 1228 | 1416 | 1630 | 1830 | 2045 | 2265 |

K | 400 | 460 | 515 | 565 | 620 | 725 | 840 | 950 | 1050 | 1160 | 1380 | 1590 | 1820 | 2020 | 2230 |

N*R | 12*22 | 16*22 | 16*26 | 20*26 | 20*30 | 24*30 | 24*33 | 28*33 | 28*36 | 32*33 | 36*36 | 40*36 | 44*39 | 48*42 | |

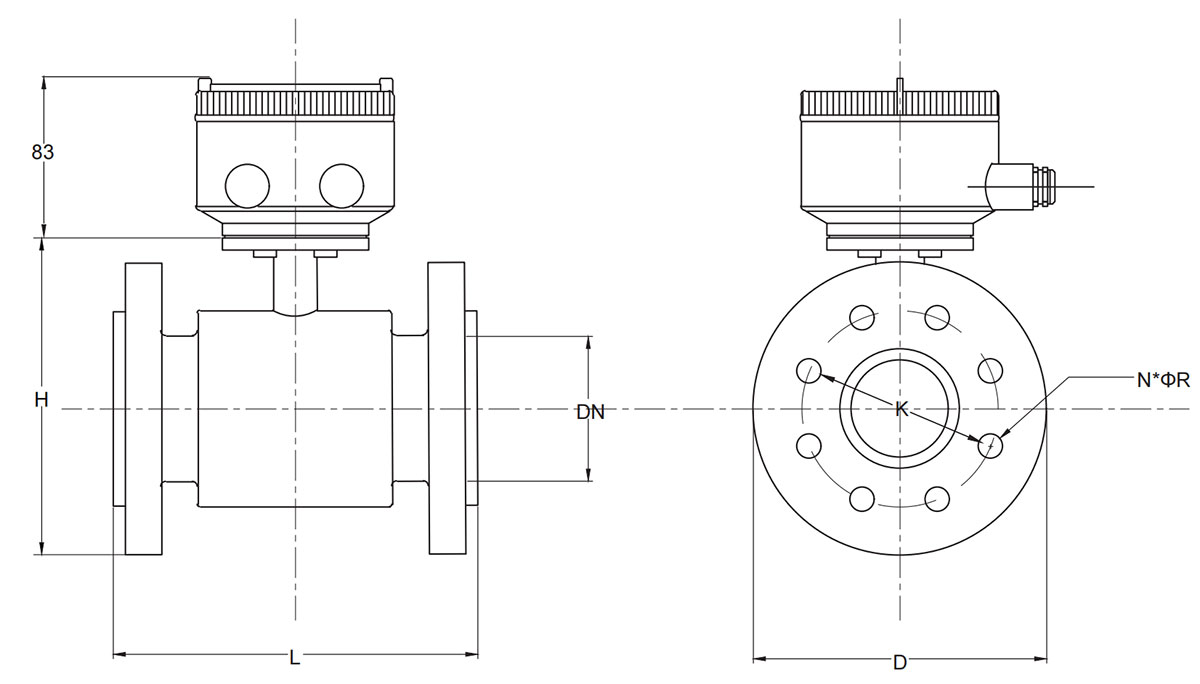

2) Flange type with junction box

Unit:mm

DN | 10a | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 |

PN(bar) | 40 | 16 | 10 | 10 | |||||||||||

L | 120 | 150 | 200 | 250 | 300 | 350 | 400 | ||||||||

D | 95 | 95 | 105 | 115 | 140 | 150 | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 395 | |

H | 142 | 142 | 147 | 152 | 172 | 177 | 205 | 216 | 228 | 258 | 284 | 315 | 366 | 420 | |

K | 60 | 65 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 350 | |

N*R | 4*14 | 4*18 | 8*18 | 8*22 | 8*22 | 12*22 | |||||||||

DN | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 |

PN(bar) | 10 | 6 | |||||||||||||

L | 450 | 500 | 600 | 700 | 800 | 900 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | |||

D | 445 | 505 | 565 | 615 | 670 | 780 | 895 | 1015 | 1115 | 1230 | 1405 | 1630 | 1830 | 2045 | 2265 |

H | 470 | 525 | 580 | 629 | 682 | 791 | 890 | 1007 | 1118 | 1228 | 1416 | 1630 | 1830 | 2045 | 2265 |

K | 400 | 460 | 515 | 565 | 620 | 725 | 840 | 950 | 1050 | 1160 | 1380 | 1590 | 1820 | 2020 | 2230 |

N*R | 12*22 | 16*22 | 16*26 | 20*26 | 20*30 | 24*30 | 24*33 | 28*33 | 28*36 | 32*33 | 36*36 | 40*36 | 44*39 | 48*42 | |

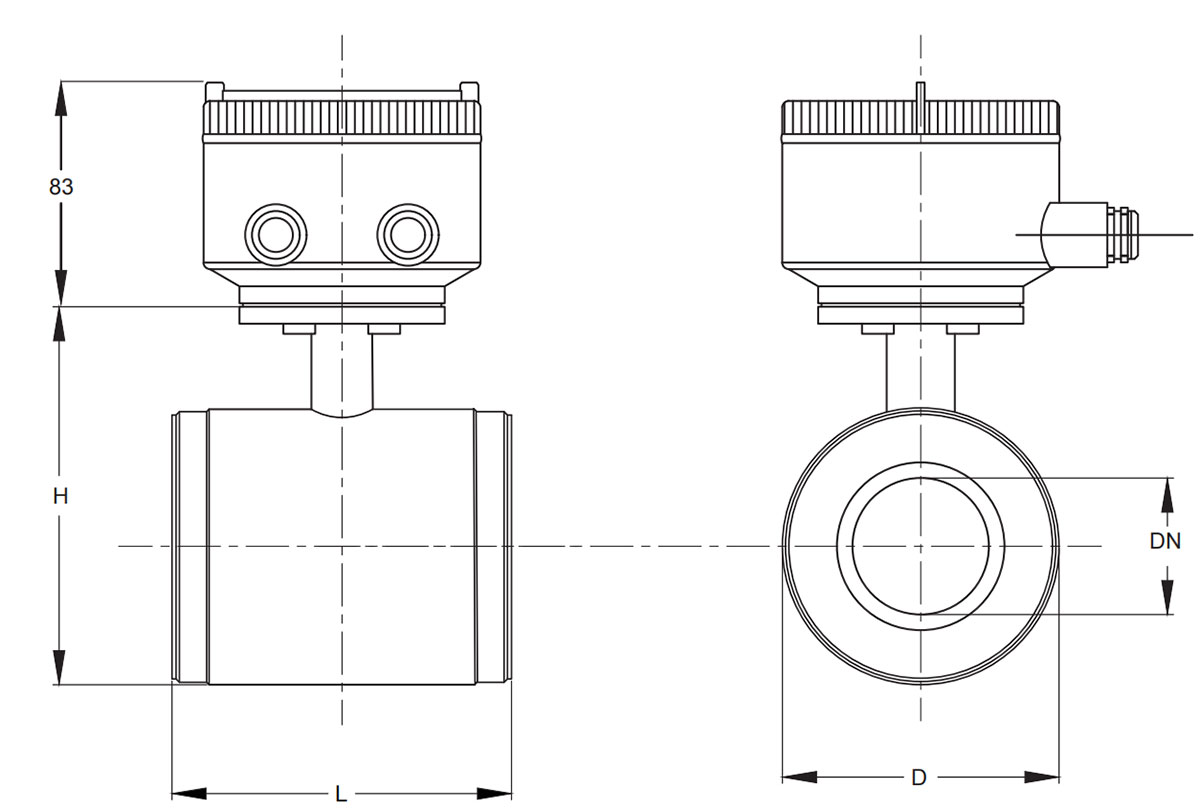

3) Sandwich type with LC display

Unit:mm

DN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

D | 67 | 76 | 82 | 96 | 116 | 127 | 147 | 177 | 202 | 257 | 320 | 372 |

L | 90 | 100 | 100 | 115 | 115 | 130 | 155 | 155 | 185 | 215 | 250 | 290 |

H | 116 | 125 | 131 | 145 | 165 | 176 | 196 | 226 | 251 | 306 | 369 | 421 |

4) Sandwich type with junction box

Unit:mm

DN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

D | 67 | 76 | 82 | 96 | 116 | 127 | 147 | 177 | 202 | 257 | 320 | 372 |

L | 90 | 100 | 100 | 115 | 115 | 130 | 155 | 155 | 185 | 215 | 250 | 290 |

H | 116 | 125 | 131 | 145 | 165 | 176 | 196 | 226 | 251 | 306 | 369 | 421 |